And I’m back after a break!

HAPPY NEW YEAR, FOLKS!!! May the year be one of fulfilment, peace, happiness and prosperity!

Some time ago, this older #Yamaha F310 came to me with a complaint of action so high that it was unplayable beyond the 5th, 6th fret.

It had a rising bridge,

which in the process of its lift,

had pulled the top too along with it, giving the instrument a more-than-healthy belly. A look inside showed the main cause of the problem – the ‘X’-brace arm on the bass side had come unglued.

Seeing the loose brace, the belly and the rising bridge, I was pretty confident that the action problem could be solved pretty easily. That was my undoing.

More on that later.

I started work with taking the old strings and the bridge off the guitar.

Not the cleanest of jobs I have done, yet nothing that I could not remedy. So, the first order of business was to get all the fibers of the top glued down to create an even surface for the bridge to reglue to.

Once this was taken care of, I reglued the loose ‘X’ brace arm, which to my understanding, was the main cause of the belly bulge and action.

The reflection in the mirror shows the brace pushed against the top, and if you look really carefully, you’ll be able to see the glue squeeze-out too.

After this was taken care of, work to cut the belly down to size began.

With each 48-hour effort, the belly was reduced some. The following photographs show the results of the last two efforts

Once I was satisfied with the results, it was time to bring the bridge and the top together.

And while the bridge remained clamped for another 48 hours, it gave me time to work on other neglected areas of the instrument – like the fretboard.

Oh, and there was also an under-saddle pick-up attached, which the owner felt had outlived its utility. He asked me to remove it. Removing the under-saddle piezo element meant creating a shortfall in the height of the saddle.

Considering all the work done on the guitar, I was sure that the saddle without the piezo element would fall terribly short and would have the strings flapping around on the fretboard. So, I buttressed the saddle not with one, not with two, but with three plastic shims. It helped that #yamaha uses plastic nuts and sadddles in the F310.

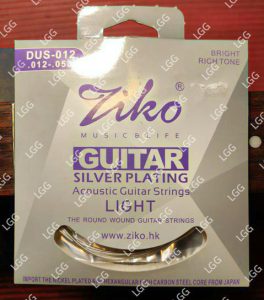

Now, all that remained to be done was to string up the instrument. The owner had chosen these

I tuned up the guitar and to my horror, it had an action high enough for a double-decker bus to pass under! I tried shaving the saddle, I tried fiddling with the truss rod, I even dialled in a lower than usual action at the first fret, but all these brought about mere cosmetic alterations.

It was then that my attention went to how and why the top under the fretboard extension had broken loose and was jutting forward in the soundhole.

I could make out that the neck block inside the guitar had come loose, and tilted forward, and with it moved the portion of the top under it. In fact, so severe was the move that the portion of the sides glued to the neck block had also moved – just about an inch on either side and along the very top of the neck-to-heel joint. I forgot to take photographs of it.

My earlier thinking that I would just be able to tap the neck block back into place, after smearing some glue behind it was grossly flawed.

Unfortunately, the neck block must have moved under string tension during the months of extreme heat, when the glue must have melted somewhat. The glue then dried on the block, sealing it in a tilted position, pulling forward everything in its contact, thus leaving no room for intervention.

The only way to solve the problem was a proper neck reset, which was too much for this old guitar – the owner’s first. As sentimental value goes, the owner would have to continue to play up until the 5th, 6th fret – after all the time and effort put into the instrument.

Though each instrument which I fail to correct, saddens me, this one was probably the saddest of all, for I knew that the owner had set his heart on playing his beloved guitar right up and down the neck and not just on the first five frets!