There are many reasons that may cause this issue. But to understand it completely, one must first understand intonation itself.

Intonation is the accuracy of the pitch of a note sounded. When you tune your guitar you do so by plucking the open (unfretted) strings. On fretting, the tension on the string increases, which generally changes the pitch of the note. The effect, though subtle, can impact the intonation.

Cutting out the jargon and putting it in simple terms, if the open note and the same note fretted sound exactly the same, your guitar is intonated. If not, then for the instrument to be perfectly intonated, adjustments have to be made to the saddle and nut, and sometimes, even to the action.

If the fretted note is sharp, the string needs to be lengthened (pushing back the contact point of the string on the saddle/nut or both).

If the fretted note is flat, the string needs to be shortened (bring the contact point of the string on the saddle/nut or both forward).

In electric guitars and basses this can be done with considerable ease but adjusting intonation in acoustic instruments involves a lot of work.

But here are a few reasons for some strings not being intonated, while others are perfectly in tune. Let’s go from the simplest and the most obvious to slightly more complicated issues.

* Unstretched new strings

Often, when new strings are put on, players forget to stretch them.

New, coiled strings are not used to the tension they are put under once a guitar is tuned up. Just like a rubberband, the tendency of new strings is to return to their original position, and thus, new strings will often go out of tune, hitting intonation.

As a matter of practice, new strings should be stretched, tuned, stretched again and re-tuned till they are able to hold the tension when they are in pitch.

* Old strings or bad strings

Old strings need to be changed because strings have a shelf life after which they don’t sound good. But sometimes, a new set can play up too. Tough luck, but you will have to change your new strings for new strings!!

*Too much relief and high action

Relief is that optimal curvature in the fretboard (which can be adjusted) which allows the strings to vibrate with ease without them hitting the frets, or, them being a mile high from the frets.

This ‘optimal curvature’ creates an optimal space between the strings and frets and is referred to as action.

It is interesting that the two things – relief and action – are hugely related and while adjusting the relief, action does get affected. However, while adjusting the action, the relief remains absolutely unchanged for it is two very different roads you take to reach Optimum Relief and Optimum Action.

If you need to adjust the relief in the neck, a proper sized Allen wrench to fit the truss rod adjustment is used, while if it is action you wish to lower, then the saddle and nut – on which the strings ride – need to be lowered by shaving them.

All this was an introduction to how relief and action affect intonation. So, if there is a big (concave) curve in the neck – big relief – the strings on that instrument are going to be riding painfully high. To fret a note on such an instrument you would have to pull the strings down so much that effectively, you would be elongating the length of the string, thus, throwing the intonation on that particular string off by miles.

An unnecessarily tall saddle and nut too raise strings uncomfortably high and we all know when the strings are high and you fret a note, what happens to that note.

*A worn saddle

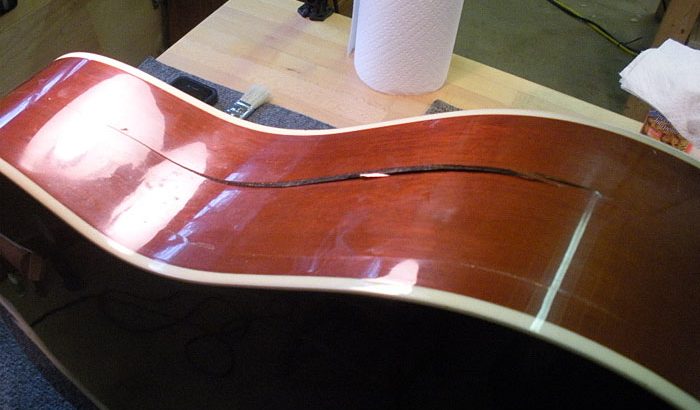

If the saddle on your acoustic guitar looks anything like this, you are in big trouble – intonation wise.

Look closely at the saddle in your guitar with the strings on. In all probability, you will find that the exact points of contacts of the six strings are not in a straight line but some contact points are pulled forward, while others are pushed back. This is to “compensate” for varying thickness of strings.

In deeply notched saddles like the one in the picture, the point of contact has gone awry and thus, this instrument will never be truly intonated till the time that a new saddle (and preferably made of bone) is not put in.

*A tilted saddle is no good

Look carefully at the photo above. Of course, you can see the space around the ends of the saddle, but look closer and you will be able to notice space behind the saddle too. This means that the saddle is tilted forward, which again throws the intonation out of whack.

Let me explain. We were talking about points of contact on the saddle in the previous point. With the saddle tilted forward, suddenly those points of contact have moved forward too, thus affecting intonation.

To correct this problem, either a new, thicker saddle (and preferably made of bone) needs to be put in the bridge slot, or, the bridge slot needs to be filled, a new proper-size slot routed out, which would seat the saddle upright.

*If the nut is too tall

Not just saddles, even the height of the nut makes a difference. The ideal action on an acoustic guitar at the 1st fret – a result of the height of the nut – is between 0.16″ and 0.18″.

To get those numbers, the nut needs to be pulled out and its bottom sanded to lower it to a proper height, so that the action at the 1st fret is just right. Again, if it is too high, you will be using extra effort to fret notes, which would cause elongation of the string, which in turn, would affect intonation.

*Bad tuning machines

If the gears on one or two or all tuning machines are slipping, then you will be tuning your guitar the entire day and it will keep falling out of tune.

If ever you encounter such a problem, chuck out those cheap tuning machines, go to your guitar tech and get a good set installed. What is a “good set”?

Tuning machines have gear ratios – the number of teeth to a gear. The more the teeth to the gears, the more finely you can tune your guitar. If you hear that a tuning machine set has a gear ratio of 1:21, it means that it would take 21 turns of the tuning machine button for the post of the machine to complete one full turn.

*Flat frets

All string instruments function on the principle of a vibrating string, where the sound produced is dependent on the length of the string. Thus, from the nut to the saddle is the effective length of the string and when you ‘fret’ a note, you change the length of that particular string, which produces the desired sound.

If while fretting a note, a fret is not in proper shape (lower photo), it will never produce the desired sound. If the fret(s) is (are) flat (Pix courtesy: jacksinstrumentservices), intonation will be affected big time.

If the frets on your instrument are not in good shape, they will have to be dressed, crowned and polished for your guitar to play the way it was intended to play.