Hello there, beautiful people!

Long time no see. Long time no hear!

Well, only I am to blame! Partly staying busy and a greater part, my laziness! Mea culpa!

I am here now and bring to you this Hertz that was brought to me by a returning customer.

It had some years on it but I could make out that once healed, it could play and sound good.

It’s problems? Well, the bridge was lifting and the saddle was tilting forward and had an odd curvature to it as it stood in its slot.

As a result, the action was sky high.

This was even though the owner had tried to shim the front face of the saddle in an effort to make the saddle stand straight.

I told the owner that once the bridge is reglued, the action will come down much, but once I make the saddle stand upright, it will again raise the action a bit. He understood.

I also told him that this would be the perfect time to get a bone nut and saddle installed, which would improve the sound of the instrument – in quality, volume and sustain. He understood that as well.

I began work with taking the strings off and as I tried to remove the saddle, it came out like this

However, my main worry was the bolts and nuts hidden beneath the two plastic dots (on either side of the bridgepins) on the bridge. Look at the photograph showing the paper shim and you will know what I am talking about.

I have often dwelt upon the uselessness of this hardware, and also the fact that they do more harm than good. Good surface-to-surface contact, enough glue, enough clamping pressure, and enough curing time will ensure that the bridge lasts on the instrument for a good two or three decades! Bolts and nuts ensure that the top is torn apart, if the bridge begins to rise.

So, the hardware had to go. The plastic dots were gently prised out of their spots and the hardware was removed. I could almost hear the guitar let out a sigh of relief!!

Then began the task of gently trying to remove the bridge. It came off but not too clean, but not too bad either. I’ve seen worse.

Both the underside of the bridge and its footprint were cleaned, glue applied and stuck together with enough clamping pressure. After that I left the instrument to dry and rest.

Unfortunately, I have lost all the photographs I took of the process – right from cleaning the bridge and its footprint to the clamping and curing process. How it happened, I am still scratching my head.

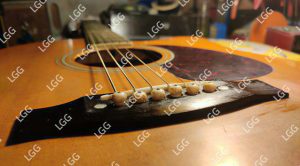

Anyway, love was also shown to the fretboard, the fretwires and the bridge. Sanded clean and with a touch of oil, they shone.

Work was also done on the swanky, new bone saddle and nut to make them fit their slots perfectly, and once they were in place, new strings were put on to get the saddle to stand straight and for optimal action to be dialled in.

From here on, it was a saga of tuning and loosening strings as I tried to dial in the correct action at the 1st fret and the 12th fret.

Here are some photographs of the finished job

Most gratifying was the reaction of the owner to the changes to his guitar. He was mighty pleased with where the action stood and remarked ‘Bone se farak to bahut hai (Bone, indeed, makes a difference)!

Hope to see you all here, soon!